How to Choose the Right Cable Gland Size: A Step-by-Step Guide

In industrial, marine, and electrical installations, the cable gland may seem like a small component, but its role is critical: securing cables, preventing ingress of dust, moisture, or corrosive substances, and ensuring long-term reliability of electrical systems. Choosing the wrong size, however, can undermine these functions—leading to leaks, cable damage, or even safety hazards. To avoid such risks, follow this step-by-step guide to select the perfect cable gland size for your application.

Step 1: Determine the Cable’s Outer Diameter (OD)

The first and most critical step is measuring the outer diameter of your cable—not the inner conductor, but the entire insulated or sheathed outer layer. This includes any armoring, braiding, or protective jackets.

1.Use a caliper for precision: Measure at the thickest point of the cable (typically near the end, where the jacket is intact).

2.Note the measurement in millimeters (mm), as cable gland sizes are standardized in metric units.

3.For multi-core cables or those with irregular shapes, take multiple measurements to ensure accuracy.

Step 2: Identify the Cable Gland’s Size Range

Cable glands are designed to accommodate a specific range of cable diameters, listed by manufacturers as “cable range” (e.g., 6mm–10mm). This range indicates the minimum and maximum cable OD the gland can securely seal.

1.Match your cable’s OD to a gland whose range includes that measurement. For example, a cable with a 8mm OD would fit a gland rated for 6mm–10mm.

2.Avoid glands where the cable OD is at the extreme edges of the range (e.g., a 10mm cable in a 8mm–10mm gland). Opt for a slightly wider range to ensure a tight seal during temperature fluctuations or vibration.

Step 3: Consider the Gland’s Thread Size (for Installation)

While the cable range focuses on the cable fit, the gland’s thread size determines compatibility with your equipment (e.g., junction boxes, enclosures, or bulkheads). Thread sizes are specified as:

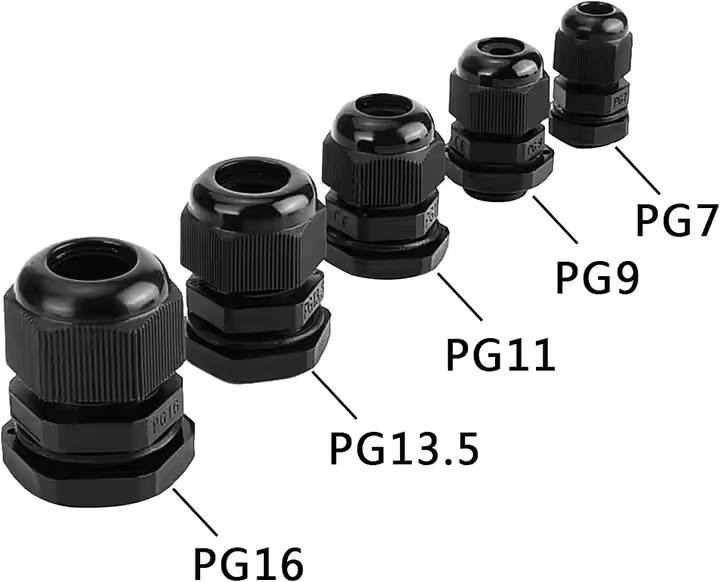

1.Metric threads: M12, M16, M20 (common in industrial settings).

2.PG threads: PG7, PG9, PG11 (popular in European installations).

3.NPT threads: 1/4”, 3/8” (used in North American markets).

4.Check your equipment’s entry port specifications to select the matching thread size. A gland with the correct cable range but wrong thread size will not install properly.

Step 4: Account for Application-Specific Factors

Environmental and operational conditions can affect size requirements. Adjust your choice based on:

1.Cable movement: If the cable is subject to flexing (e.g., in machinery), choose a gland with a larger range to accommodate slight diameter changes under stress.

2.Temperature extremes: In high-heat or cold environments, cables may expand or contract. Select a gland with a range that accounts for these variations.

3.Ingress protection (IP) needs: For IP66/IP68 rated glands (water/dust tight), ensure the cable OD fits snugly within the range to maintain the seal—even a small gap can compromise protection.

Step 5: Verify Compatibility with Cable Type

Different cables (e.g., armored, unarmored, braided) require specialized glands, each with unique sizing considerations:

1.Unarmored cables: Use standard glands with a compression ring to seal the jacket.

2.Armored cables: Choose glands with armor clamps, ensuring the clamp size matches the armoring’s diameter (not just the inner cable OD).

3.High-voltage or hazardous area cables: Glands for EX zones (ATEX/IECEx certified) have stricter size tolerances—always cross-reference with the manufacturer’s safety data.

Step 6: Consult Manufacturer Specifications

Finally, cross-check your measurements with the manufacturer’s datasheet for the chosen gland model. Reputable brands (e.g., Weidmüller, Lapp, or Hubbell) provide detailed charts linking cable OD, thread size, and application limits.

1.Look for notes on “maximum fill” (for multi-cable glands) or special instructions for coated cables.

2.When in doubt, contact the manufacturer’s technical support with your cable details—they can recommend the exact size for your needs.

Why Precision Matters

A properly sized cable gland ensures a secure seal, prevents premature failure, and maintains compliance with safety standards (e.g., IEC, NEC, or ATEX). Whether for a factory floor, offshore platform, or renewable energy site, taking the time to measure and match sizes will save time, cost, and headaches in the long run.

Choose wisely—your system’s reliability depends on it.