The explosion proof armored double sealing cable gland represents the perfect combination of ruggedness and reliability. Its multi-clamp design provide unparalleled retention and sealing for armored cables. Its explosion-proof performance makes it widely used in hazardous locations such as oil extraction, refining, chemical processing, and military applications. The following is an introduction to core parameters, performance features, specifications, pricing, and purchasing information:

I. Core Parameters and Performance Features

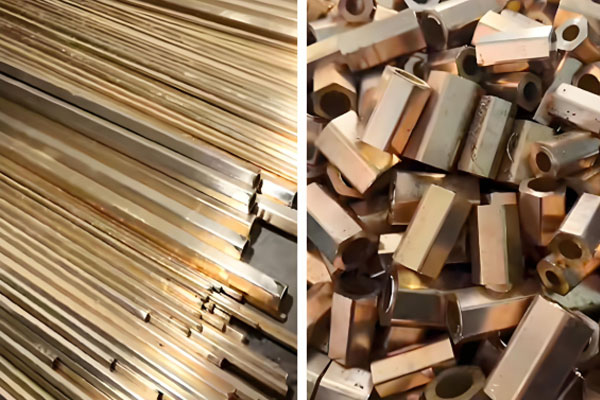

Material and Craftsmanship

The main body is available in nickel-plated brass, 304 stainless steel, and 316 stainless steel, offering excellent corrosion resistance, mechanical strength, and durability, suitable for a wide range of chemical and physical environments.

Fully Explosion-Proof Certifications: Explosion-proof ratings meet Ex db IIC Gb; Ex eb IIC Gb; and Ex tb IIIC Db, making it suitable for most explosive gas and dust environments, ensuring safe operation in hazardous areas.

Waterproof Sealing: Achieves IP66 protection, completely protecting against dust ingress and intrusion from strong waves or powerful water jets.

Wide Temperature Range: Silicone seals ensure stable performance in extreme temperatures ranging from -60°C to +100°C.

Adaptability: Perfectly matches and clamps a variety of armored cables, including wire armor, braid armor, and steel tape armor, and is compatible with various interface standards, including metric M-thread and US NPT.

II. Main Specifications

Product specifications are mainly divided into M-type, NPT-type, and G-type.

Note: Some models can be customized; please contact the seller to confirm specific specifications.

Applicable environment: oil exploitation, refining, chemical industry, military industry and other hazardous areas; Zone 1,2 of explosive gas environments, Zones 20,21,22 of combustible dust environments, and IIA,IIB,IIC explosive gas environments; also suitable for armoured cables and cable wiring, as well as tight sealing of cable clips with wire, braided or steel tape armouring.