In numerous industrial and electronic equipment applications, Anti - bending Cable Glands play a crucial role. They can protect cables and ensure the safety and stability of cable connections under various complex environments and usage conditions. However, with a wide variety of products available in the market, how to choose the right Anti - bending Cable Glands according to your own needs has become a key issue. This article will provide you with a comprehensive selection guide based on the detailed product information on chuangda.

1. Understand the Application Scenario and Environmental Requirements

(1) Environmental Factors

Waterproof and Dustproof Requirements

If your equipment will be used in wet or dusty environments, such as outdoor lighting equipment, automated control systems in sewage treatment plants, etc., you need to choose Anti - bending Cable Glands with a high waterproof and dustproof rating. The products provided on chuangda have a protection level of IP68, which can effectively prevent the ingress of water and dust. This level of protection is achieved by using an O - ring seal within the specified bayonet range and tightening the tightening head, ensuring the reliability of the product in harsh environments.

Chemical Corrosion Resistance

For equipment used in industries such as chemical, marine, or food processing, cable glands may come into contact with various chemicals, such as acids, alkalis, oils, greases, and general solvents. In this case, you should choose products with corresponding chemical corrosion resistance. For example, the Anti - bending Cable Glands on chuangda are resistant to weak acids, oils, greases, and general solvents, and some are also resistant to acids, alkalis, alcohol, etc. If there are specific chemicals in your application environment, you can further communicate with the supplier to confirm whether the product is suitable or whether special materials can be customized to meet your needs.

Temperature Adaptability

chuangda is - 40℃~100℃ statically, with an instant heat resistance of up to 120℃; and - 20℃~80℃ dynamically, with an instant heat resistance of up to 100℃. If your equipment operates under extreme temperature conditions, you need to carefully evaluate the temperature performance of the selected product to ensure that it can maintain flexibility at low temperatures and not deform or be damaged at high temperatures.

(2) Equipment Movement and Vibration Conditions

Anti - bending and Anti - torsion Requirements

If the equipment connected by the cable moves, rotates frequently, or is subject to vibration, such as robot arms, movable industrial equipment, or vehicle - mounted electronic systems, etc., anti - bending and anti - torsion performance is particularly important. The spiral anti - torsion mechanism of Anti - bending Cable Glands can effectively prevent the cable from being damaged due to excessive torsion, especially during equipment movement or manual operation. This mechanism can ensure that the cable outlet does not experience excessive twisting and guarantee the safe transmission of the cable. When choosing a product, pay attention to its anti - bending and anti - torsion design features and its performance in actual use.

Strain Relief Function

The movement and vibration of the equipment may also cause the cable to bear tension and stress, so the strain relief function is indispensable. Appropriate Anti - bending Cable Glands should be able to relieve the stress on the conductor and insulation through their structure and materials under pulling, bending, or vibration conditions, avoid damage, and extend the cable life. When evaluating the product, understand the principle and effect of its strain relief to ensure that it can adapt to the movement pattern of your equipment and effectively protect the cable.

2. Determine the Cable Specification and Size

(1) Cable Diameter Matching

Accurate Measurement of Cable Outer Diameter

Refer to the Product Cable Range Parameters

chuangda provides detailed product parameter tables, which clearly list the cable range applicable to each model of Anti - bending Cable Glands. For example, the Pg7 model is suitable for cables with a diameter of 3 - 6.5mm, and the PG9 model is suitable for cables with a diameter of 4 - 8mm, etc. According to the outer diameter of the cable you measured, select the product model whose cable range can cover this size. Ensure that the cable range of the selected model is neither too large to cause poor sealing nor too small to be installed.

(2) Consider the Flexibility and Rigidity of the Cable

Special Requirements for Flexible Cables

If you are using a flexible cable, such as some thin cables used for data transmission or robot control, you need to choose a cable gland that can adapt to its flexibility. An overly rigid gland may limit the bending radius of the cable, leading to premature cable damage. In this case, pay attention to whether the design of the gland allows the cable to bend freely within a certain range while maintaining a good connection and protection.

Stability Requirements for Rigid Cables

For rigid cables, such as power cables, the focus should be on the fixing and supporting ability of the gland. Ensure that the selected Anti - bending Cable Glands can firmly fix the cable, prevent it from shaking or moving at the connection point, and thus avoid damage caused by friction and vibration. At the same time, the structure of the gland should be able to bear the weight of the cable and the possible external forces.

3. Select the Appropriate Thread Type and Size

(1) Applicability of Thread Types

Understanding of Common Thread Standards

chuangda offers Anti - bending Cable Glands with various thread types, including PG, M, NPT, and G standards. PG threads are commonly used in the European market, such as in the German military and other fields; M threads are metric threads and are widely used globally; NPT threads are the American standard national pipe threads and are common in the North American market; G threads also have a certain application range. Understanding the thread standard followed in your region or by your equipment will help narrow down the selection range.

Select the Thread Type According to the Equipment Interface

Check the thread type of the cable interface on the equipment and ensure that the selected Anti - bending Cable Glands matches it. If the thread types do not match, the gland cannot be installed correctly, resulting in a loose connection or poor sealing. If you are unsure about the thread type of the equipment, you can refer to the equipment manual or consult the equipment manufacturer.

(2) Thread Size Matching

Importance of Thread Diameter and Length

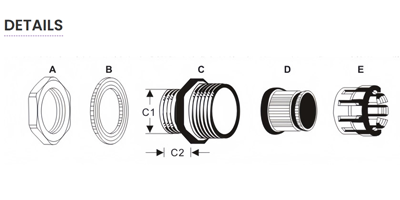

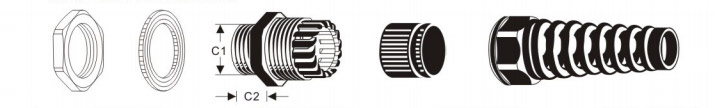

The thread diameter (C1) and thread length (C2) must match the equipment interface. A thread diameter that is too large or too small may lead to installation difficulties or a loose connection. Similarly, insufficient thread length may not provide enough tightening force, while excessive length may cause unnecessary waste or conflict with the internal structure of the equipment. Refer to the product parameter table on chuangda and select Anti - bending Cable Glands with thread sizes that exactly match the equipment interface.

Consideration of Wrench Diameter and Nut Diagonal Size

When installing and disassembling the cable gland, you need to use a wrench of the corresponding size. The wrench diameter (A) and nut diagonal (A) sizes in the product parameters provide this information. Ensure that you have the appropriate size tools to ensure smooth operation during installation and maintenance. If you do not have the right tools, it may lead to improper installation or damage to the gland.

4. Pay Attention to the Product Material and Quality

(1) Performance of the Main Body Material

Advantages of Nylon Main Body:

chuangda is usually made of nylon. Nylon has good mechanical properties, such as high strength and good toughness, and can withstand a certain amount of external force without being easily damaged. At the same time, it also has good chemical corrosion resistance and can resist the erosion of chemicals in the environment to a certain extent. In addition, the nylon material is relatively light, which is convenient for installation and use, and has a certain insulation performance, which helps improve the safety of cable connections.

Selection of Customizable Materials:

If your application environment has special requirements, such as low temperature, high temperature, high alkali, or strong corrosion, chuangda offers the option of customizing materials. For example, you can customize materials such as cold - resistant, high - temperature - resistant rubber, high - alkali - resistant, chemical - resistant, and corrosion - resistant rubber for seals and O - rings. Selecting the appropriate customized material according to the actual needs can ensure that the cable gland can still work normally in extreme environments and extend the service life of the product.

(2) Quality Certification and Reliability

Importance of Product Quality Certification,Methods for Evaluating Product Quality

In addition to certification, you can also preliminarily evaluate the quality of the product by looking at its appearance quality, material texture, processing technology, etc. High - quality Anti - bending Cable Glands usually have a smooth surface, no burrs, clear threads, and the sealing and O - ring materials are uniform without bubbles or cracks. In addition, referring to the evaluations and reputations of other users to understand the performance of the product in actual use can also help judge its quality reliability.

5. Consider the Additional Functions and Features of the Product

(1) Color Customization and Identification

Purpose of Color Customization

chuangda offers Anti - bending Cable Glands in white, black, and other customized colors. In some complex equipment systems, by customizing cable glands of different colors, it is convenient to distinguish and identify the lines.

For example,:in a large - scale automated production line, different color glands can represent different functions or signal lines, which is convenient for installation, maintenance, and troubleshooting.

Importance of Identification Function

Some high - end Anti - bending Cable Glands may also have an identification function, such as marking the model, specification, production date, and other information on the gland. These markings are helpful for quickly obtaining product information during equipment maintenance and management, ensuring the correct selection of spare parts and timely replacement. If your equipment management requires detailed recording and tracking of cable glands, products with an identification function will be a good choice.

(2) Installation and Maintenance Convenience

Design Features for Easy Installation

Choosing Anti - bending Cable Glands that are easy to install can save time and labor costs. Some products may have special designs, such as quick - connection structures, guiding devices, or pre - assembled parts, which make the installation process simpler and faster. Although the convenience features of installation are not detailed in the product introduction on chuangda, you can consult the supplier to understand the difficulty of operation and the required tools during the installation process, and ensure that you choose a product that suits your installation ability and conditions.

Considerations for Easy Maintenance

During the service life of the equipment, the cable gland may need to be regularly inspected, maintained, or replaced. Therefore, it is very important to choose a product that is easy to maintain. For example, the structure of the gland should be easy to disassemble and reinstall, the seals and O - rings should be easy to replace, and no additional damage should be caused to the cable during the maintenance process. In addition, the maintainability of the product should also be considered, such as whether there are replaceable parts and whether the maintenance cost is reasonable.

chuangda