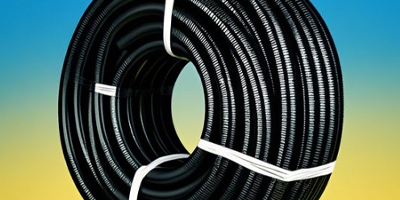

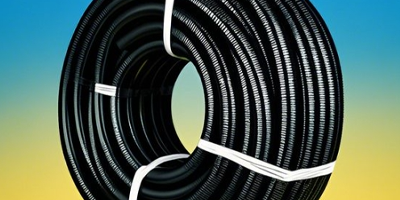

In modern engineering construction, the importance of piping systems is self-evident. And as an important part of pipe connections, plastic bellows connect fittings are providing strong guarantees for the efficient operation of piping systems with their unique advantages.

①The advantages of plastic bellows connect fittings are first reflected in their materials. Common materials include polyvinyl chloride (PVC), polypropylene (PP), etc. These engineering plastics possess excellent corrosion resistance, insulation, and mechanical strength. For example, PVC connect fittings can remain stable in different chemical environments, effectively preventing the corrosion of pipes by substances such as acids and alkalis, and prolonging the service life of the piping system. PP material has higher heat resistance and pressure resistance, and is suitable for some piping systems with higher requirements for temperature and pressure, such as fluid transportation pipes in chemical production.

②Secondly, the connection methods of plastic bellows connect fittings are innovative and convenient. Adopting the quick insertion type connection technology, the installation process is greatly simplified. Construction workers only need to accurately insert the bellows into the interface of the connect fitting to complete the connection, without the need for professional tools and complicated operating skills. This connection method can not only save a large amount of installation time and labor costs but also ensure the sealing and reliability of the connection. Moreover, the special structural design of the connect fitting endows the pipe with a certain flexibility, enabling it to adapt to the displacement and deformation of the pipe caused by factors such as temperature changes and foundation settlement during the operation process, effectively avoiding the problems of pipe rupture and leakage due to stress concentration.

③In terms of application range, plastic bellows connect fittings are widely used in multiple fields such as construction, chemical industry, agriculture, and communication. In the construction field, they can be used for indoor and outdoor water supply and drainage systems, ventilation systems, and the connection of protective sleeves for electrical lines, providing guarantees for the normal use of buildings. In the chemical industry, their corrosion resistance and high-temperature resistance enable them to safely transport various highly corrosive and high-temperature chemical media, ensuring the continuity and stability of chemical production. In agricultural irrigation, plastic bellows connect fittings can be laid flexibly according to different topographies and landforms to achieve efficient water-saving irrigation. In communication engineering, they can provide good protection for cable lines, preventing the cables from being damaged by external factors and ensuring the stable transmission of communication signals.

④To fully exert the performance of plastic bellows connect fittings, the following points need to be noted during the use process. First, it is necessary to ensure that the specifications of the fittings match those of the bellows to avoid situations where the connection is not tight or cannot be connected due to size discrepancies. Second, during the installation process, attention should be paid to the operation specifications to ensure that the insertion depth meets the requirements, so as to ensure the sealing and stability of the connection. Third, for piping systems used in harsh environments for a long time, it is necessary to regularly inspect and maintain the connect fittings, promptly detect and replace damaged fittings, so as to prolong the service life of the piping system.

⑤In conclusion, plastic bellows connect fittings have become an indispensable part of modern piping systems with their excellent performance, convenient connection methods, and wide application fields. They provide reliable guarantees for the efficient operation of piping systems and make important contributions to the development of various industries. With the continuous progress of science and technology and the continuous expansion of application fields, it is believed that plastic bellows connect fittings will play an even more important role in future piping construction.

In modern engineering construction, the importance of piping systems is self-evident. And as an important part of pipe connections, plastic bellows connect fittings are providing strong guarantees for the efficient operation of piping systems with their unique advantages.

In modern engineering construction, the importance of piping systems is self-evident. And as an important part of pipe connections, plastic bellows connect fittings are providing strong guarantees for the efficient operation of piping systems with their unique advantages.