A Comprehensive Guide to Nickel-Plated Brass Anti-Bend Cable Glands: Uses, Materials & Selection Tips

In the world of electrical and mechanical installations, security and longevity are paramount. One critical, yet often overlooked, component that ensures both is the cable gland. Specifically, Nickel-Plated Brass Anti-Bend Cable Glands have become a gold standard for demanding applications. This guide will break down what they are, why they're used, and how to choose the right one.

What Are Nickel-Plated Brass Anti-Bend Cable Glands?

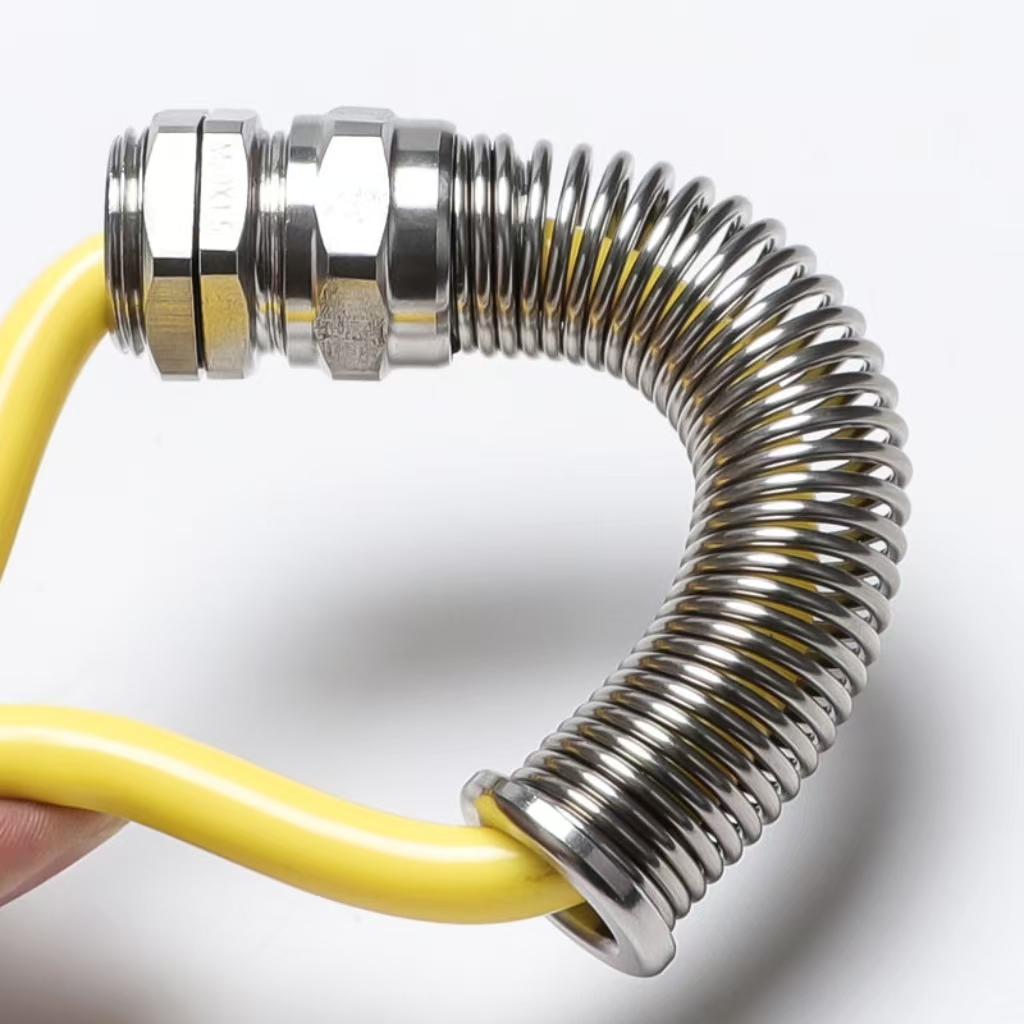

At their core, cable glands (or cable connectors) are devices used to securely attach and seal the end of an electrical cable to equipment. They provide strain relief, preventing forces from being transferred to the electrical connections, and they seal out contaminants like dust and water.

The Nickel-Plated Brass Anti-Bend Cable Gland is a specialized type:

- Brass Body: The base material is brass, an alloy of copper and zinc. Brass is chosen for its excellent mechanical strength, corrosion resistance, malleability, and good electrical conductivity.

- Nickel Plating: A layer of nickel is electroplated onto the brass. This enhances the gland's surface properties, providing superior corrosion resistance, increased hardness for abrasion resistance, and a sleek, aesthetically pleasing chrome-like finish.

- Anti-Bend Design: This is the key functional feature. Also known as anti-vibration or strain-relief glands, they incorporate an internal neoprene or rubber seal and a conical clamping mechanism. When tightened, this system grips the cable's outer jacket firmly but gently, preventing it from bending sharply at the entry point. This protects the internal copper conductors from fatigue, breakage, and pull-out forces.

- Brass Body: The base material is brass, an alloy of copper and zinc. Brass is chosen for its excellent mechanical strength, corrosion resistance, malleability, and good electrical conductivity.

- Nickel Plating: A layer of nickel is electroplated onto the brass. This enhances the gland's surface properties, providing superior corrosion resistance, increased hardness for abrasion resistance, and a sleek, aesthetically pleasing chrome-like finish.

- Anti-Bend Design: This is the key functional feature. Also known as anti-vibration or strain relief glands, they incorporate an internal neoprene or rubber seal and a conical clamping mechanism. When tightened, this system grips the cable's outer jacket firmly but gently, preventing it from bending sharply at the entry point. This protects the internal copper conductors from fatigue, breakage, and pull-out forces.

Key Uses and Applications

Nickel-Plated Brass Anti-Bend Cable Glands are not for every simple wiring job. Their enhanced properties make them ideal for challenging environments:

1. Industrial Machinery: On production lines with constant vibration, shock, and movement, these glands prevent cable failure at connection points.

2. Marine & Offshore Applications: The combination of brass and nickel plating offers excellent resistance to saltwater corrosion and harsh weather conditions.

3. Outdoor & HVAC Equipment: Used in equipment exposed to rain, UV radiation, and temperature fluctuations, providing a secure seal and mechanical protection.

4. Automation & Robotics: In applications where cables are in continuous motion or flexing, the anti-bend feature is crucial for long-term reliability.

5. Washdown Areas & Food & Beverage Processing: The corrosion-resistant, easy-to-clean nickel-plated surface is suitable for humid or chemically cleaned environments.

6. Telecommunications & Data Centers: Used to protect data and power cabling in racks and cabinets, ensuring integrity against accidental tugs and bends.

Breaking Down the Materials: Why Nickel-Plated Brass

- Brass (The Core): Offers a great balance of strength and ductility. It is naturally more corrosion-resistant than plain steel and is resistant to sparking, making it suitable for volatile atmospheres.

- Nickel Plating (The Shield): Brass alone can tarnish and corrode under extreme conditions. The nickel plating acts as a sacrificial and inert barrier. It significantly slows down oxidation (tarnishing) and resists a wide range of chemicals, moisture, and abrasion, extending the gland's life dramatically.

- Comparison: While plastic glands are cost-effective for light duty, and stainless steel offers maximum corrosion resistance for highly aggressive chemical environments, **nickel-plated brass glands** sit perfectly in the middle—offering robust protection, durability, and conductivity at a reasonable cost for most industrial applications

Essential Selection Tips

Choosing the right Nickel-Plated Brass Anti-Bend Cable Gland involves several factors:

1. Cable Diameter: This is the most critical step. Measure the outer diameter (OD) of your cable's jacket accurately. Glands are specified with a minimum and maximum cable range (e.g., 8-12mm). Ensure your cable fits snugly within this range for a proper seal and grip.

2. Ingress Protection (IP) Rating: This indicates the level of sealing against solids and liquids. For outdoor or wet locations, look for a minimum of IP68 (dust-tight and protected against prolonged immersion).

3. Thread Type and Size: Determine the entry thread of the enclosure you're connecting to (e.g., M20, M25, PG13.5, NPT 1/2"). The gland's thread must match exactly.

4. Material & Plating Quality: Ensure the product specifies "nickel-plated brass." Reputable manufacturers will use a sufficiently thick plating layer for durability.

5. Certifications: For use in regulated industries, check for relevant certifications like UL, CSA, IECEx, or 0ATEX(for hazardous areas).

6. Internal Seal Compatibility: The internal rubber seal (often included) should be compatible with your cable's jacket material (e.g., PVC, PUR) and the environmental conditions (ozone, oil, temperature).

Installation Best Practices

1. Always disassemble the gland (separate the locking nut, seal, and clamping rings) before threading the cable through.

2. Insert the cable, then reassemble the gland components in the correct order on the cable.

3. Hand-tighten the gland into the enclosure before using a tool for the final quarter to half turn. Do not over-tighten, as this can damage the cable, crush the seal, or strip the threads.

4. Ensure the anti-bend cone properly compresses and grips the cable jacket without cutting into it.

Conclusion

Nickel-Plated Brass Anti-Bend Cable Glands are engineered solutions for reliability. They combine the strength of brass with the protective shield of nickel plating and the cable-preserving function of an anti-bend mechanism. By understanding their uses, material advantages, and following clear selection criteria, you can ensure a secure, durable, and professional installation that protects valuable equipment and prevents costly downtime. Investing in the right gland is a small step that guarantees a giant leap in system integrity.