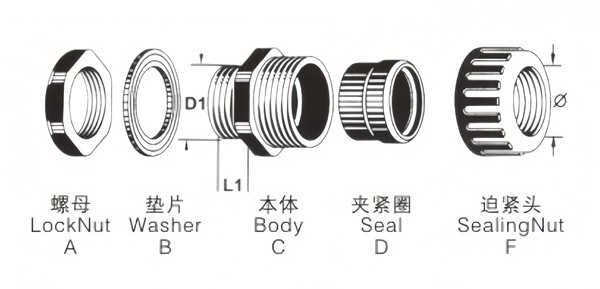

The The PE Bellows Pipe Gland is a component used to connect bellows and equipment. Its main feature is good waterproof performance. This joint usually consists of two main parts: Part A.C.F and Part D. The A.C.F part is made of nylon, a material with high flame retardancy and heat resistance. Part D is made of weather-resistant rubber, which has good weather resistance, acid and alkali resistance, and chemical corrosion resistance.

Protection Degree: Within the specified bayonet range and use an O-ring to tighten the tightening head, the protection level reaches IP68

Color: light gray, black, and other customized color

How to use: First, put the main body through the machine board, then tighten it with the nut. The hose passes through the tightening head and goes into the clamping ring to the bottom. Tighten the tightening head to fix it.

Application: Bellows waterproof joints are widely used in mobile automation equipment for waterproof, oil-proof and air-tight applications. Because they can withstand high pulling forces and remain airtight, they are ideal for applications that require frequent movement and connection. The application fields of these joints include but are not limited to engineering machinery, agricultural machinery, shipbuilding, petrochemical and other industries.

OEM: Support