Crafted from premium brass with a precision-engineered nickel-plated finish, PG Thread Industrial Cable Glands deliver exceptional durability and corrosion resistance for robust electrical connectivity. Designed to excel in demanding environments, these glands combine high-gloss aesthetics with superior mechanical strength, ensuring long-term reliability. Available in a comprehensive range of PG thread sizes (PG7 to PG48), Chuangda seamlessly adapt to diverse cable diameters (0.5mm²–120mm²) and equipment interfaces, making them ideal for industrial automation, machinery, and outdoor installations requiring waterproof, dustproof, and UV-resistant solutions.

Key Features

High-grade brass core with nickel plating for enhanced corrosion and abrasion resistance.

Polished surface maintains aesthetic appeal in industrial settings.

PG7 to PG48 thread options to fit cables from 0.5mm² to 120mm².

IP68-rated sealing (optional) for waterproof and dustproof performance in harsh conditions.

UV-resistant and chemical-resistant properties for extended outdoor use.

Working Temperature: The working temperature ranges of different products vary. Static -40℃~100℃ or instantly heat resistance up to 120℃. Dynamic -20℃~80℃ or Instant heat resistance to 100℃.

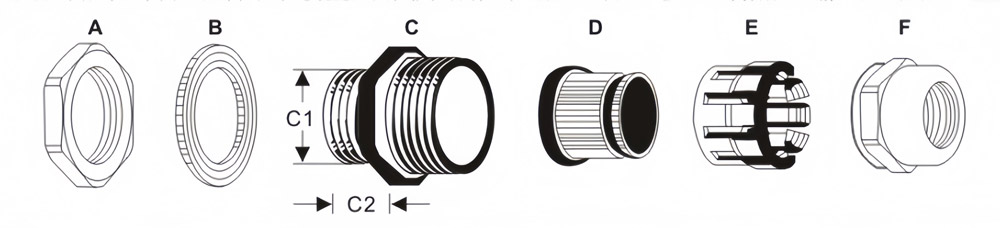

Dimensions parameters:There are clear parameters for dimensions such as thread outer diameter and thread length. For example, the outer diameter of the thread affects the tightness of the connection between the joint and the equipment, while the thread length is related to the stability and sealing of the connection. Appropriate thread size design can ensure that the connector is not easy to loosen after connection, effectively preventing the cable from falling off the connector or foreign matter entering the connector and causing damage to the cable.