The metal expanding adaptor is an efficient solution for pipe diameter connection and expansion. Its precision metal structure and multiple sealing designs ensure reliable connection and media flow guidance for different-diameter pipes, guaranteeing the piping system's tightness, seismic resistance, and environmental adaptability. It is widely used in scenarios requiring stringent pipeline stability, such as large-scale power plant supporting projects, medical gas transportation, and sewage treatment projects.

I. Core Parameters and Performance Features

Material and Craftsmanship

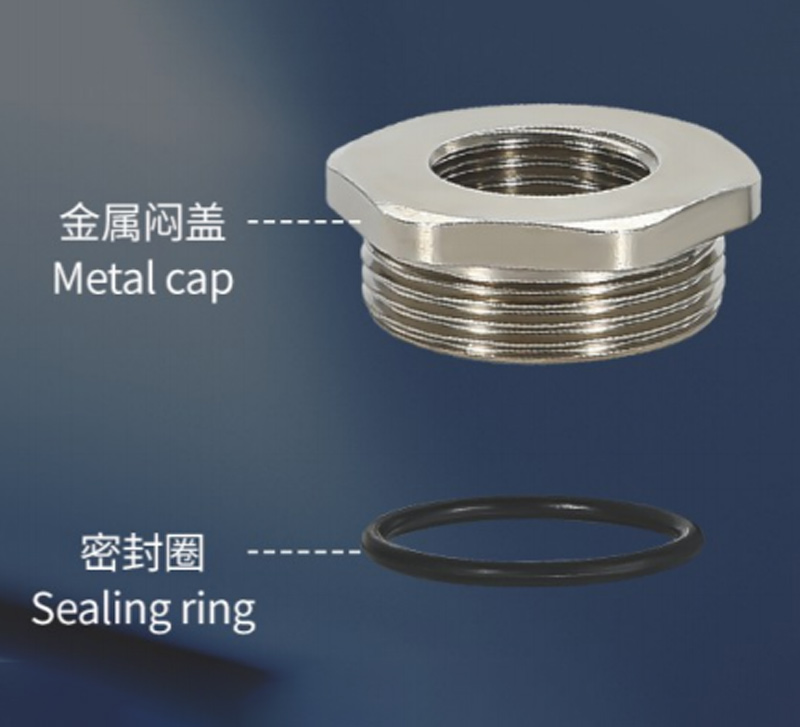

The main body is nickel-plated brass, with excellent mechanical strength and corrosion resistance, suitable for oil, moisture, acid-alkali and other complex industrial environments. The surface coating has a bright white appearance and long-lasting anti-oxidation performance.

Reliable Connection Performance

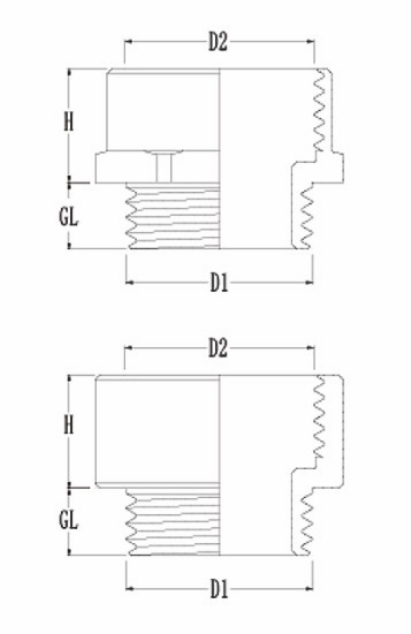

The adjustable thread structure enables stable expansion of two different-diameter pipe sections, preventing media leakage and interface stress concentration, ensuring long-term stable operation of the system.

Wide Temperature Range

It operates stably at -40°C to +100°C, adapting to extreme hot and cold conditions, and maintaining structural stability and sealing performance.

Integrated Protection

Protection Rating: IP68 (completely dustproof, resistant to long-term submersion)

Sealing Materials: The waterproof ring adopts nitrile rubber, PTFE, silicone and other composite materials, providing multiple sealing guarantees, and resisting chemical agents and aging.

Vibration and Displacement Resistance

Metal material and threaded locking structure provide mechanical support, alleviating stress from pipeline vibration and displacement, and reducing system failure risk.

II. Mainstream Specifications

The product interface threads are mainly Metric (M-type) and Inch (G-type), which can be flexibly selected according to project requirements.