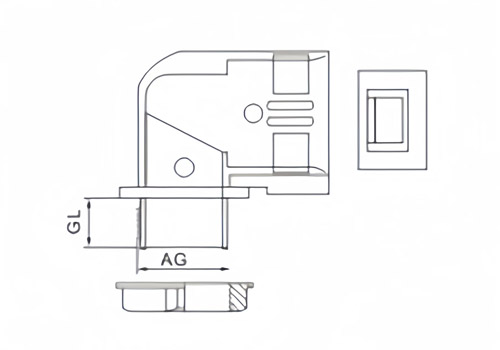

90 degree bellows fittings connect is a special pipe connection that is mainly used to change the direction of the pipe, especially when the pipe is required to make a right-angle turn. This type of joint usually consists of a corrugated pipe and a right-angle elbow. The elastic properties of the corrugated pipe enable it to adapt to the thermal expansion, contraction and vibration of the pipe to a certain extent, thus protecting the entire pipe system from damage.

Feature: The inner lock and body are specially designed, and only need to be removed and unplugged without tools.

Application: Bellows pipe right-angle connectors are widely used in many fields, such as in the construction field for pipe connections in drainage, heating and air conditioning systems; in the petrochemical industry to ensure the reliable connection of various liquid and gas transmission pipes; in automobile manufacturing , can be used in automobile oil pipes, air pipes and other systems; in the aerospace field, there are extremely high requirements for lightweight and reliability, and bellows joints can meet these needs; in municipal engineering, such as urban water supply, gas supply and sewage treatment systems It is present in.