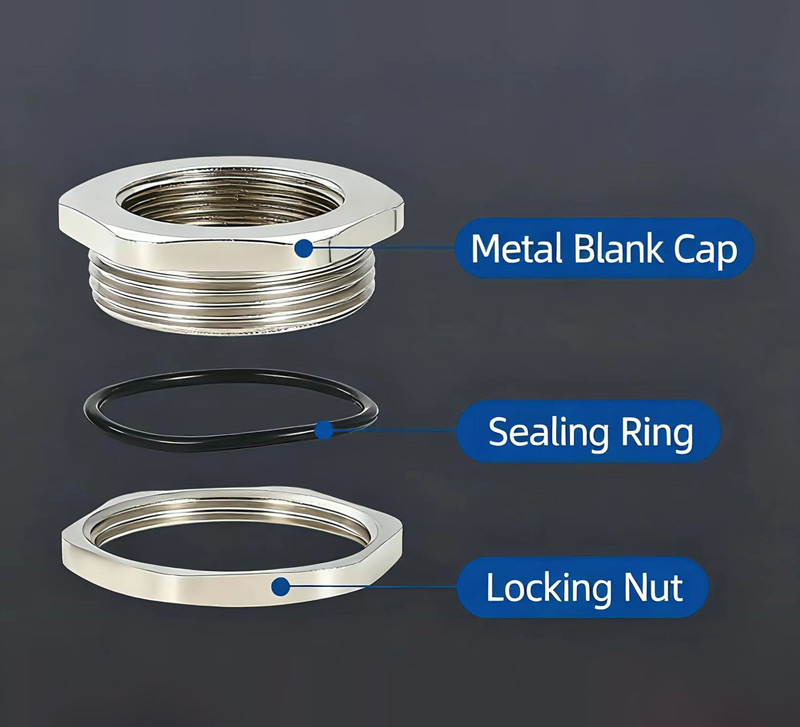

The metal reducing adaptor are an efficient solution for integrated cable and hose management and strain relief. Their precision metal structure and threaded locking design allow them to bundle and secure multiple cables and seal their ports, effectively eliminating vibration and preventing environmental corrosion. They are widely used in industrial automation, electrical control, outdoor equipment, and other applications where cable stability is critical.

I. Core Parameters and Performance Feature

Material and Craftsmanship

The main body is made of nickel-plated brass, offering both high mechanical strength and corrosion resistance, making it suitable for complex industrial environments such as oily and humid environments. The surface coating provides long-lasting anti-oxidation protection.

Strong Locking Performance

Using uniform radial compression, they securely bundle cables of varying diameters, preventing vibration-induced wear and loosening of connectors.

Vibration and Displacement Resistance

The compact threaded locking mechanism (manual installation) combined with the rigid metal support keeps cable groups secure in dynamic vibration environments, preventing the risk of fatigue fracture. Wide Temperature Range

Static Environment: Applicable Temperature -40°C to +120°C

Dynamic Environment: Applicable Temperature -20°C to +80°C Ensures tightness and sealing in extreme temperatures, suitable for cold start and high-temperature operation.

Integrated Protection

Protection Rating: IP68 (protects against dust and splash water intrusion)

Electromagnetic Shielding: The metal body suppresses external signal interference

Weather and Corrosion Resistance: Resists UV rays, salt spray, and acid and alkali media

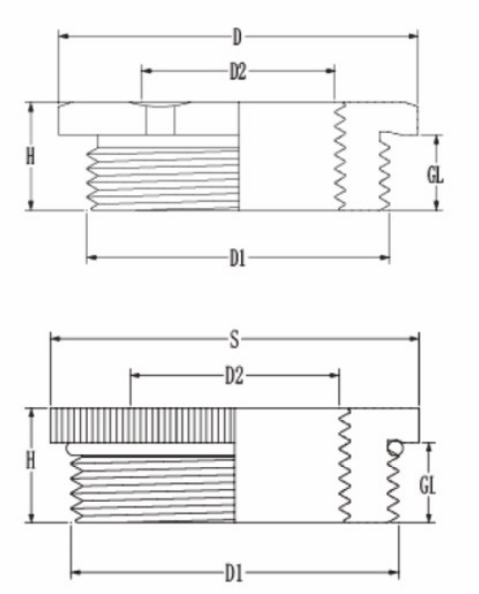

II. Mainstream Specifications

Product interface threads are mainly divided into:

Metric thread (M type) and German thread (PG type)