MG split cable gland is a common cable connection accessory. It is mainly used to fix and seal cables to ensure the safe and stable operation of cables in various environments. Split cable gland is a component used to connect and fix cables. It is usually made of materials such as metal and nylon and has good waterproof, dustproof and corrosion resistance.

Material: The main part of the MG Split Type Cable Gland is made of nylon, and the clamping part as well as seals and O-rings are made of nitrile rubber. Cold-resistant, high-temperature-resistant rubber, high-alkali-resistant, chemical-resistant and corrosion-resistant rubber also can be customized.

Protection Degree: IP68. The IP68 protection degree signifies that this cable management solution is highly resistant to dust and water ingress. Specifically, it can prevent the entry of dust completely (the first digit, '6') and withstand continuous immersion in water under specified conditions (the second digit, '8'). This high level of protection is ensured through the use of an O-ring seal that tightens the head securely within the designated bayonet range. Such a design makes it well-suited for harsh usage environments where exposure to elements like water, dust, and other contaminants is a concern.

Working Temperature Degree: The operating temperature ranges of different products vary. Static -40℃~100℃ or instantly heat resistance up to 120℃. Dynamic -20℃~80℃ or Instant heat resistance to 100℃.

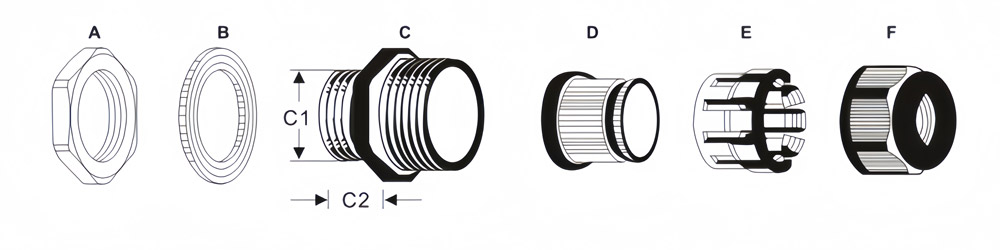

Product features: special design of clamping claws and clamping ring, tightening nut with elastic buckle, large clamping range of cables, strong tensile strength, waterproof, dustproof, salt-resistant, weak acid, alcohol, and oil resistance , grease and general solvents 3.

Scope of application: Used in power electronic control equipment, military industry, petroleum, chemical industry, explosion-proof, textile, medical, aviation communications, machine tool machinery and equipment manufacturing, measurement and control technology, instrument manufacturing and many other industries with plastic-coated hoses. Cable and wire connectors.