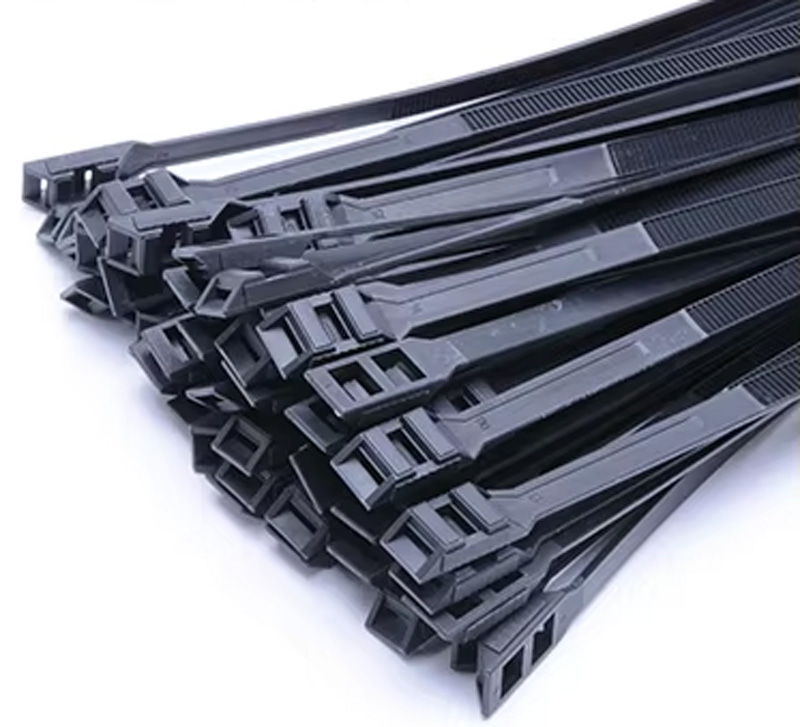

Double-locking nylon cable ties are a cable securing solution designed specifically for high-vibration environments. Their unique double-locking structure and external serrations ensure long-lasting, stable fastening while minimizing wear on wires, cables, and hoses. Suitable for industrial equipment, electrical controls, outdoor installations, and other applications requiring high vibration and abrasion resistance, they are available in bulk and small-batch packaging.

I. Core Parameters and Performance Features

Material and Craftsmanship

The main body is made of environmentally friendly PA66 nylon, which offers high strength, corrosion resistance, and excellent electrical insulation.The outward-facing clamping teeth prevent damage to the cable surface and enhance vibration resistance.

Protection Rating: IP66 (dust-proof and water-resistant), suitable for use in humid or dusty environments.

Flammability Rating: UL 94-V2 certified, effectively flame-retardant in open flame environments. Temperature Range: -40℃ to +85℃ (short-term resistance up to +110℃); Installation Temperature Range: -20℃6 to +85℃.

Chemical Resistance: Resistant to alkalis, oils, greases, petroleum derivatives, and chlorinated solvents; limited resistance to acids; not suitable for phenolic environments.

Humidity Adaptability: Moisture absorption is only 2.7% (23℃-50% R.H.), providing high stability.

Mechanical Properties

High tensile strength and toughness enable self-locking fastening, preventing loosening after long-term use.

External serrations enhance retention in vibrating environments while reducing wear on sensitive materials.

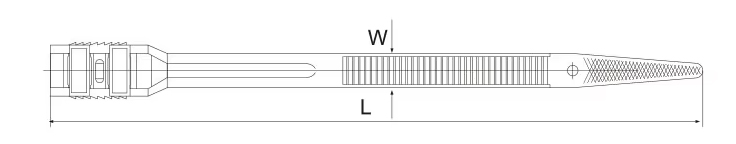

II. Mainstream Specifications

Standard Model: CHDA-180DL (black, 180mm length, 9mm width)

Certifications: CE and ROHS certified, meeting environmental and electrical safety requirements.

Customization Support: Custom sizes, colors, and temperature ranges (such as high-temperature-resistant seals) are available.

III.Application Scenarios

Cable securing and protection for mechanical equipment, harness management within electrical control cabinets, waterproof and dustproof wiring for outdoor equipment, and cable fastening in high-vibration environments (such as rail transit and heavy machinery).

Application: Used for securing cables and corrugated conduits and providing waterproof protection. Suitable for harsh environments such as machinery, electrical installations, and outdoor environments where exposure to moisture, low and high temperatures, oil, or where flame retardancy and insulation are required. Resistant to alkalis, oils, greases, petroleum derivatives, and chlorinated solvents; limited resistance to acids; not phenolic.