Core Advantages · Rugged Protection Solutions

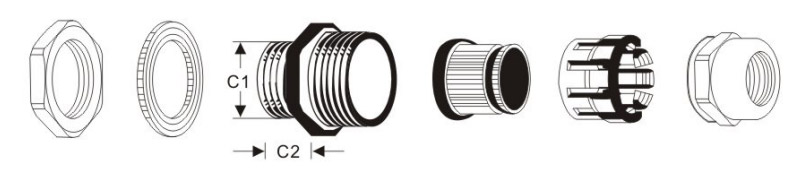

This NPT threaded stainless steel cable gland series is engineered for harsh industrial environments. Crafted from premium 304/316 stainless steel, it delivers IP68 waterproof and dustproof performance, compatible with 3–52mm cable diameters. Ideal for oil and gas, marine engineering, rail transit, and other demanding applications requiring secure cable sealing.

Extreme Environmental Durability

• Explosion-Proof Design: Double-layer silicone sealing rings for enhanced safety in volatile environments.

Wide Temperature Tolerance: Stable performance from -40℃ to 100℃ static use, with instant heat resistance up to 120℃.

• Corrosion Resistance: Superior anti-rust performance, perfect for coastal or chemical-exposed areas.

• Vibration & Pull-Proof: 360° rotating locking mechanism withstands 20N·m torque and mechanical stress.

Technical Specifications

• Thread Sizes: NPT1/4, NPT3/8, NPT1/2, NPT3/4, NPT1, NPT1-1/4, NPT1-1/2, NPT2, NPT2-1/2 (Tapered Pipe Thread)

• Cable Range: 3–52mm (supports rubber, armored, corrugated cables)

• Protection Rating: IP68 (submersible up to 1m for 48 hours; optional IP69K for high-pressure washdown)

• Surface Finish: Mirror-polished (Ra≤0.8μm) to prevent dirt accumulation.

Key Applications

• Oil & Gas: Explosion-proof cable sealing for drilling rigs and pipelines.

• Marine Equipment: Saltwater-resistant connections for ships and offshore platforms.

• Food Processing: Washdown-ready glands for hygienic machinery.

• Rail Systems: Vibration-resistant junctions for signaling and power lines.

• Renewable Energy: UV-resistant terminals for solar/wind installations.

• Industrial Automation: EMI-shielded cable ports for robotics.

• Low-Temperature Storage: Freeze-proof seals for cold chain logistics.

• Heavy Machinery: Reinforced strain relief for mining/construction equipment.

Engineering Highlights

√ Self-Locking Compression: Dual-cone sealing technology ensures zero loosening under vibration.

√ Anti-Corrosion Coating: Triple-layer nickel-chrome plating (≥25μm thickness).

√ Easy Installation: Hexagonal knurled flange for slip-proof grip.

Selection Tips

① Marine/Coastal Use: Opt for 316L stainless steel + PTFE seals.

② High-Temperature Zones: Choose heat-resistant silicone gaskets.

③ Heavy Vibration Areas: Prioritize models with secondary locking nuts.

④ Chemical Exposure: Select PTFE-coated variants for acid/alkali resistance.