Precision-Engineered Cable Glands for Demanding Environments:

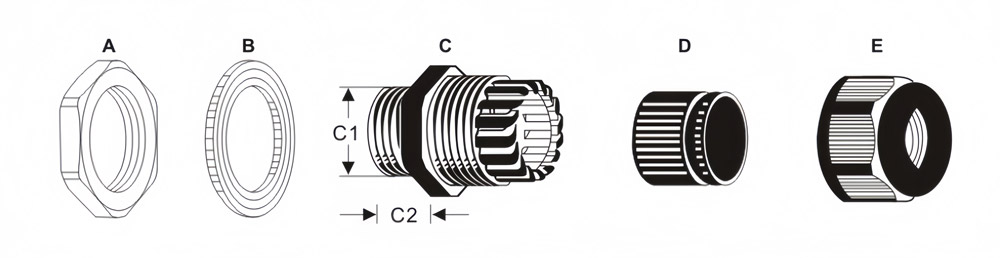

Crafted with G-thread connectivity and weatherproof nylon construction, this versatile cable gland series delivers robust protection across industrial applications. Available in compact mini cable gland variants for 4-12mm cables and heavy-duty models up to 44mm, the system ensures secure cable retention while adapting seamlessly to enclosures, devices, and solar installations through customizable threading.

Key Applications

Hazardous cable gland solutions: Flame-retardant nylon and corrosion-resistant seals meet safety requirements for oil/gas, chemical plants, and explosive atmospheres.

Solar cable gland specialization: UV-stabilized materials and extended temperature tolerance (-40℃~120℃) ensure reliability in photovoltaic systems and outdoor energy infrastructure.

Cross-industry adaptability: From rail transit motors to automated robotics, ports, and wind turbines.

Advanced Material Science

Nylon PA66 body: High tensile strength with IP68/IP69K ingress protection.

Nitrile rubber seals: Resistant to oils, weak acids, and solvents (optional fluororubber for extreme conditions).

Dynamic stress relief: Reinforced clamping zones prevent cable slippage under vibration.

Performance Features

Dual environmental shielding against dust, salt spray, and pressurized water jets.

Chemical resilience compatible with solar panel cleaning agents and industrial degreasers.

Instant thermal tolerance for welding sparks near machinery or desert solar farms.

Certified Connectivity

Designed for direct integration with explosion-proof junction boxes, solar inverters, and mobile equipment panels. Optional conductive variants available for grounding compliance in hazardous areas.